parts shop

Individual pieces & hardware

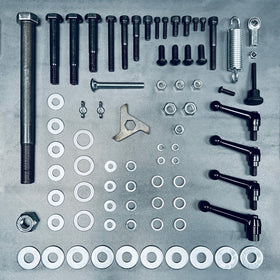

We're expanding the parts segment of HouseMade and offering many of the Revolution components and hardware pieces for sale individually.

Whether you're having trouble sourcing some of the parts yourself or customizing your grinder beyond the build, we have you covered.